Aluminum rubber, often referred to as rubber-aluminum, is a composite material that combines the properties of rubber with the structural advantages of aluminum. This versatile material finds applications in a wide range of industries due to its unique combination of flexibility, resilience, and the strength and lightweight characteristics of aluminum. In this detailed description, we will explore the construction, properties, benefits, and various applications of aluminum rubber.

Construction:

Aluminum rubber is typically fabricated by bonding a layer of rubber or elastomeric material to a sheet or strip of aluminum. The rubber layer is securely adhered to the aluminum substrate using various adhesive techniques, such as vulcanization, adhesive bonding, or mechanical fastening. The result is a composite material that combines the distinct properties of both rubber and aluminum.

Properties and Characteristics:

- Flexibility and Resilience: The rubber component of aluminum rubber provides flexibility and resilience, allowing the material to deform and absorb energy when subjected to stress or impact. This property makes it suitable for applications requiring vibration damping and shock absorption.

- Strength and Lightweight: Aluminum, known for its high strength-to-weight ratio, contributes durability and structural integrity to the composite. This makes aluminum rubber strong yet lightweight, making it ideal for applications where weight reduction is essential.

- Corrosion Resistance: Aluminum is naturally resistant to corrosion, ensuring the durability of the composite in various environmental conditions. This property is particularly advantageous in outdoor or marine applications.

- Thermal Insulation: Aluminum rubber exhibits thermal insulating properties due to the low thermal conductivity of rubber. This characteristic is useful in applications where thermal insulation is required.

- Electrical Insulation: The rubber component of aluminum rubber provides electrical insulation, making it suitable for electrical enclosures and applications where electrical conductivity must be avoided.

- Sound Absorption: The inherent flexibility and damping properties of rubber contribute to sound absorption, making aluminum rubber suitable for noise reduction applications.

Benefits:

The unique combination of properties in aluminum rubber offers several advantages across a wide range of applications:

- Vibration Damping: Aluminum rubber is effective in reducing vibrations and shock, making it valuable in machinery mounts, automotive suspension systems, and industrial equipment.

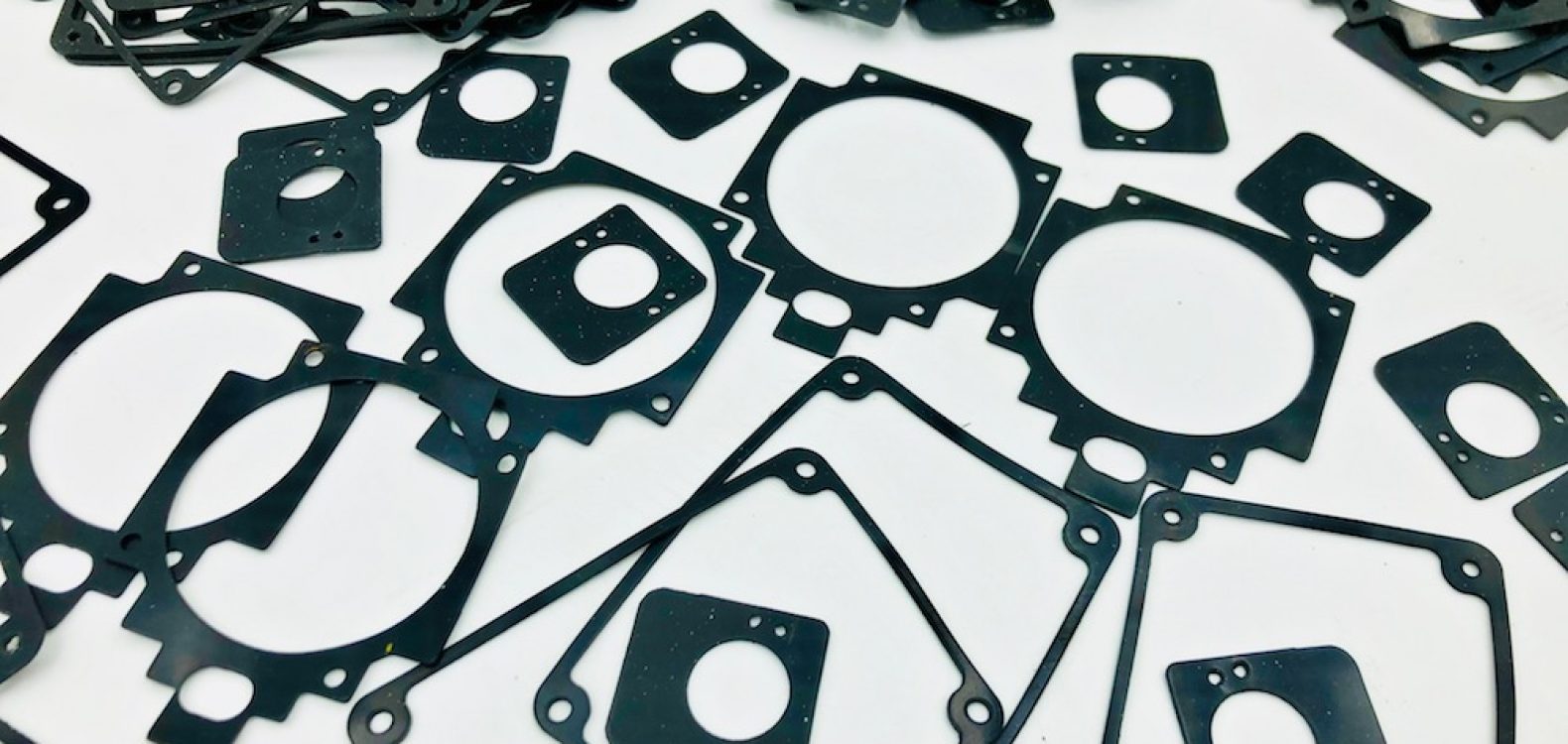

- Weather Resistance: Its resistance to corrosion and environmental factors makes aluminum rubber suitable for outdoor applications, such as weather seals, gaskets, and marine components.

- Lightweight Structural Components: Aluminum rubber can be used to create lightweight structural elements, such as panels and enclosures, without sacrificing strength.

- Noise Control: The sound-absorbing properties of aluminum rubber are valuable in automotive soundproofing, HVAC systems, and architectural acoustics.

- Impact Protection: In applications where impact resistance is crucial, such as bumpers and protective shields, aluminum rubber can absorb and dissipate energy, reducing damage and wear.

Applications:

Aluminum rubber is employed in various industries and applications, including:

- Automotive: It is used in automotive suspension bushings, engine mounts, and vibration isolation systems.

- Aerospace: Aluminum rubber is applied in aircraft components, including vibration dampers and noise control elements.

- Marine: It finds use in marine gaskets, seals, and structural components due to its corrosion resistance.

- Construction: In the construction industry, it is used for sealing applications, as weatherstripping, and in building facades for thermal insulation and noise reduction.

- Industrial Equipment: Aluminum rubber is used in machinery mounts, conveyor belts, and shock absorbers.

- Electrical Enclosures: Its electrical insulation properties make it suitable for electrical panel gaskets and insulation.

- Architectural Acoustics: It contributes to noise control in architectural applications, including theaters, studios, and commercial buildings.

In conclusion, aluminum rubber is a versatile composite material that combines the properties of rubber and aluminum, offering a wide range of benefits and applications in industries where flexibility, resilience, and strength are essential. Its ability to absorb vibrations, provide thermal and electrical insulation, and resist corrosion makes it a valuable material in diverse fields, from automotive and aerospace to construction and marine applications.