Concrete pipe seals are essential components used in various construction and infrastructure projects involving concrete pipes. These seals are designed to ensure watertight and secure connections between concrete pipes, preventing leaks, infiltration of groundwater or soil, and the escape of sewage or other fluids. In this description, we will explore the construction, functions, benefits, and applications of concrete pipe seals.

Construction and Materials:

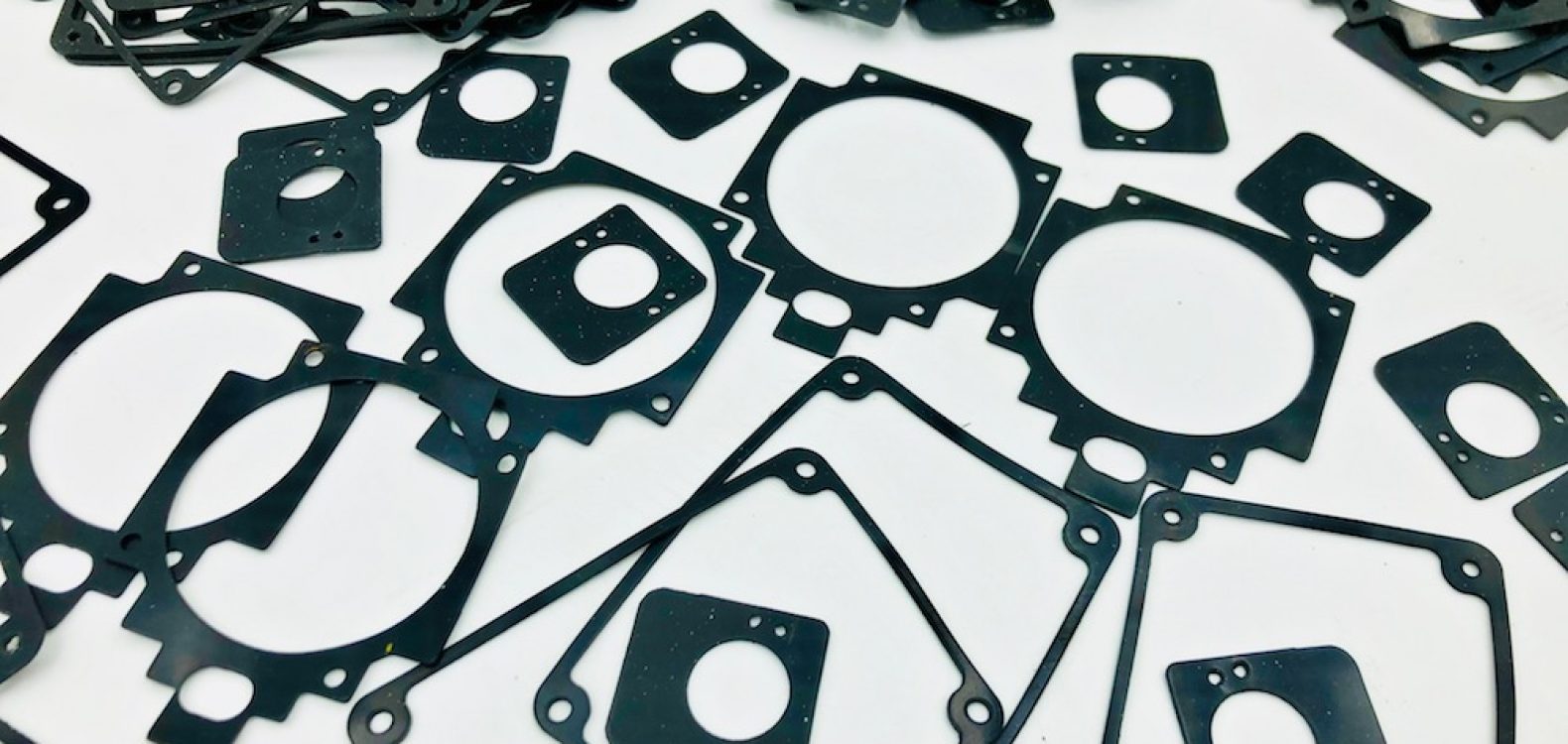

Concrete pipe seals are typically constructed using durable and resilient materials chosen for their ability to withstand the demanding conditions within concrete pipe systems. Key components of concrete pipe seals include:

- Elastomeric Material: The core of the seal is made of elastomeric materials such as EPDM (Ethylene Propylene Diene Monomer) rubber or neoprene. These materials provide flexibility, resilience, and a reliable sealing mechanism.

- Reinforcing Elements: Some concrete pipe seals incorporate reinforcing elements such as embedded steel wires or fabric to enhance their strength and durability.

- End Rings: Many concrete pipe seals feature end rings, often made of stainless steel, that help secure the seal in place and prevent it from extruding or slipping out of position when pipes are joined.

Functions and Benefits:

Concrete pipe seals serve several critical functions:

- Leak Prevention: The primary purpose of these seals is to create a watertight and airtight seal between concrete pipes, preventing leaks of water, sewage, or other fluids.

- Infiltration and Exfiltration Control: Concrete pipe seals help control the infiltration of groundwater or soil into the pipe system and the exfiltration of wastewater or pollutants out of the pipes, which is crucial for environmental protection.

- Pressure Containment: They ensure that the pressure within the concrete pipe system remains stable and within design limits, even under varying flow rates and loads.

- Corrosion Resistance: Elastomeric materials used in concrete pipe seals are resistant to corrosion, making them suitable for use in harsh environments and with various types of fluids.

- Easy Installation: Concrete pipe seals are designed for ease of installation, reducing labor costs and installation time.

Applications:

Concrete pipe seals are used in a wide range of applications and industries, including:

- Sewer and Wastewater Systems: They are a critical component of sewer and wastewater pipelines, ensuring a reliable and long-lasting seal to prevent sewage leakage and contamination.

- Stormwater Management: In stormwater drainage systems, concrete pipe seals help manage water runoff and prevent soil infiltration into the pipes.

- Water Treatment Plants: Concrete pipe seals are used in water treatment facilities to transport clean water or treated wastewater.

- Culverts and Bridges: They are employed in culverts and bridge construction for water conveyance and erosion control.

- Infrastructure Projects: Concrete pipe seals are integral to infrastructure projects such as road and highway drainage systems, underground utility installations, and industrial pipelines.

- Residential and Commercial Construction: These seals are used in construction projects for building drainage, foundation drainage, and other applications where concrete pipes are utilized.

In summary, concrete pipe seals play a crucial role in maintaining the integrity and functionality of concrete pipe systems across various sectors. Their ability to prevent leaks, control infiltration and exfiltration, and resist corrosion makes them essential components for ensuring the reliability and longevity of infrastructure and construction projects. Concrete pipe seals are an indispensable element in modern sewage and drainage systems, contributing to environmental protection and public health.