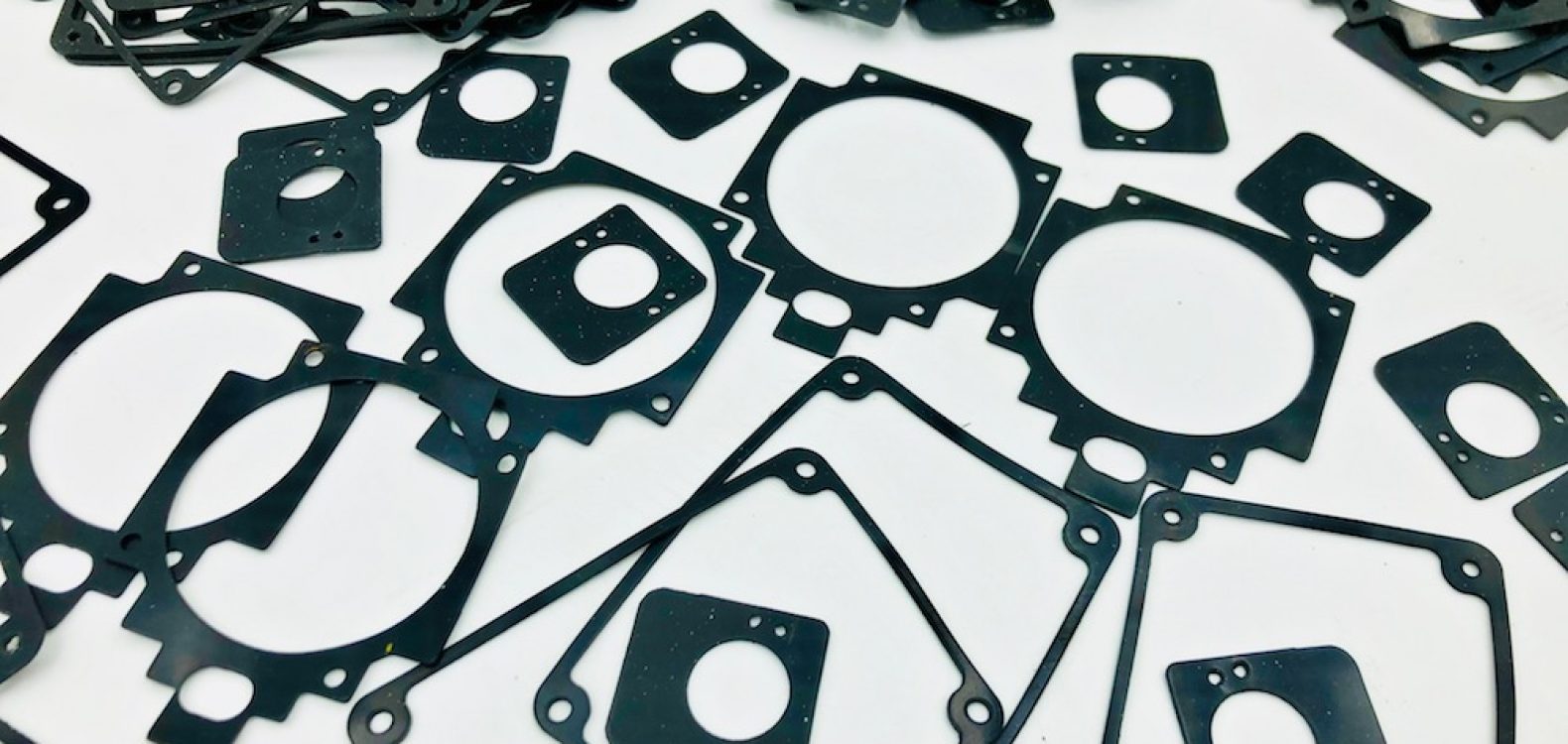

EPDM (Ethylene Propylene Diene Monomer) rubber seals are essential components used in a variety of industries and applications for sealing, insulation, and protection against environmental factors. EPDM is a synthetic rubber known for its excellent resistance to weathering, UV radiation, ozone, and a wide range of chemicals, making it a popular choice for seals in diverse settings. Here’s a detailed description of EPDM rubber seals, including their construction, properties, applications, and benefits.

Construction and Materials:

EPDM rubber seals are typically manufactured using a vulcanization process, which involves cross-linking the EPDM polymer chains with sulfur or other cross-linking agents. This process enhances the rubber’s flexibility, resilience, and resistance to environmental factors. EPDM seals may also include reinforcing elements, such as fabric or metal inserts, to improve their strength and stability.

Properties and Characteristics:

EPDM rubber seals exhibit a range of valuable properties:

- Weather Resistance: EPDM seals excel in outdoor applications due to their exceptional resistance to weathering, UV radiation, and ozone exposure. They maintain their integrity and sealing capabilities in harsh environmental conditions.

- Chemical Resistance: EPDM is known for its resistance to a wide range of chemicals, acids, bases, and polar solvents. This property makes EPDM seals suitable for use in various industrial settings.

- Temperature Tolerance: EPDM rubber remains flexible and functional across a broad temperature range, from -40°C (-40°F) to 150°C (302°F). This versatility allows for both low-temperature sealing and high-temperature insulation.

- Resilience and Compression Set Resistance: EPDM seals maintain their shape and sealing properties even after compression and release, preventing permanent deformation known as “compression set.”

- Electrical Insulation: EPDM rubber has excellent electrical insulating properties, making it suitable for use in electrical enclosures and gaskets.

- Low Gas Permeability: EPDM exhibits low gas permeability, which is beneficial for sealing applications, preventing the escape of gases or the intrusion of contaminants.

- Tensile Strength: EPDM rubber possesses good tensile strength, contributing to its durability and resistance to tearing or ripping.

Applications:

EPDM rubber seals find extensive applications in a wide range of industries and settings, including:

- Automotive: EPDM seals are used in automotive applications, such as door seals, window seals, gaskets, and hose connections, for their weather resistance and durability.

- Construction: In the construction industry, EPDM seals are used as weatherstripping, gaskets, expansion joint seals, and roofing seals to prevent water infiltration and maintain energy efficiency.

- HVAC (Heating, Ventilation, and Air Conditioning): EPDM seals are employed in HVAC systems for duct sealing, vibration damping, and insulation.

- Electrical Enclosures: EPDM gaskets provide electrical insulation and environmental protection in electrical enclosures, control panels, and junction boxes.

- Aerospace: In the aerospace sector, EPDM seals are used in aircraft windows and seals due to their resistance to extreme temperatures and UV radiation.

- Marine: EPDM seals are used in marine applications, including boat hatches, portholes, and seals, where they must withstand exposure to saltwater and sunlight.

- Industrial Manufacturing: Various industrial equipment and machinery incorporate EPDM seals for sealing, insulation, and chemical resistance.

- Food and Beverage: EPDM rubber seals are used in food and beverage processing equipment because of their compatibility with food-grade applications and sanitation requirements.

- Medical Devices: EPDM seals are employed in medical devices and equipment due to their biocompatibility and resistance to sterilization processes.

In summary, EPDM rubber seals are versatile sealing components with a wide range of applications across industries. Their exceptional weather resistance, chemical resistance, temperature tolerance, and electrical insulation properties make them valuable for sealing, insulation, and protection in diverse settings, contributing to improved product performance and longevity.