PVC (Polyvinyl Chloride) pipe seals are integral components used in a wide range of applications to maintain the performance and integrity of PVC piping systems. These seals play a crucial role in preventing leaks, maintaining pressure, and safeguarding the environment across various industries and settings, including construction, plumbing, irrigation, wastewater management, and more. To provide a comprehensive understanding of PVC pipe seals, let’s delve into a detailed description of their construction, function, benefits, and applications.

Construction and Materials:

PVC pipe seals are constructed using a combination of materials that offer durability and resistance to environmental factors. Key components typically include:

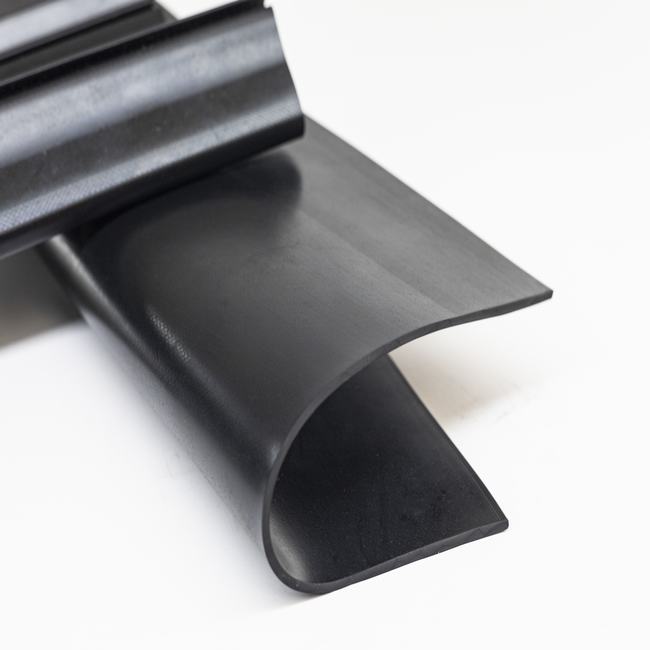

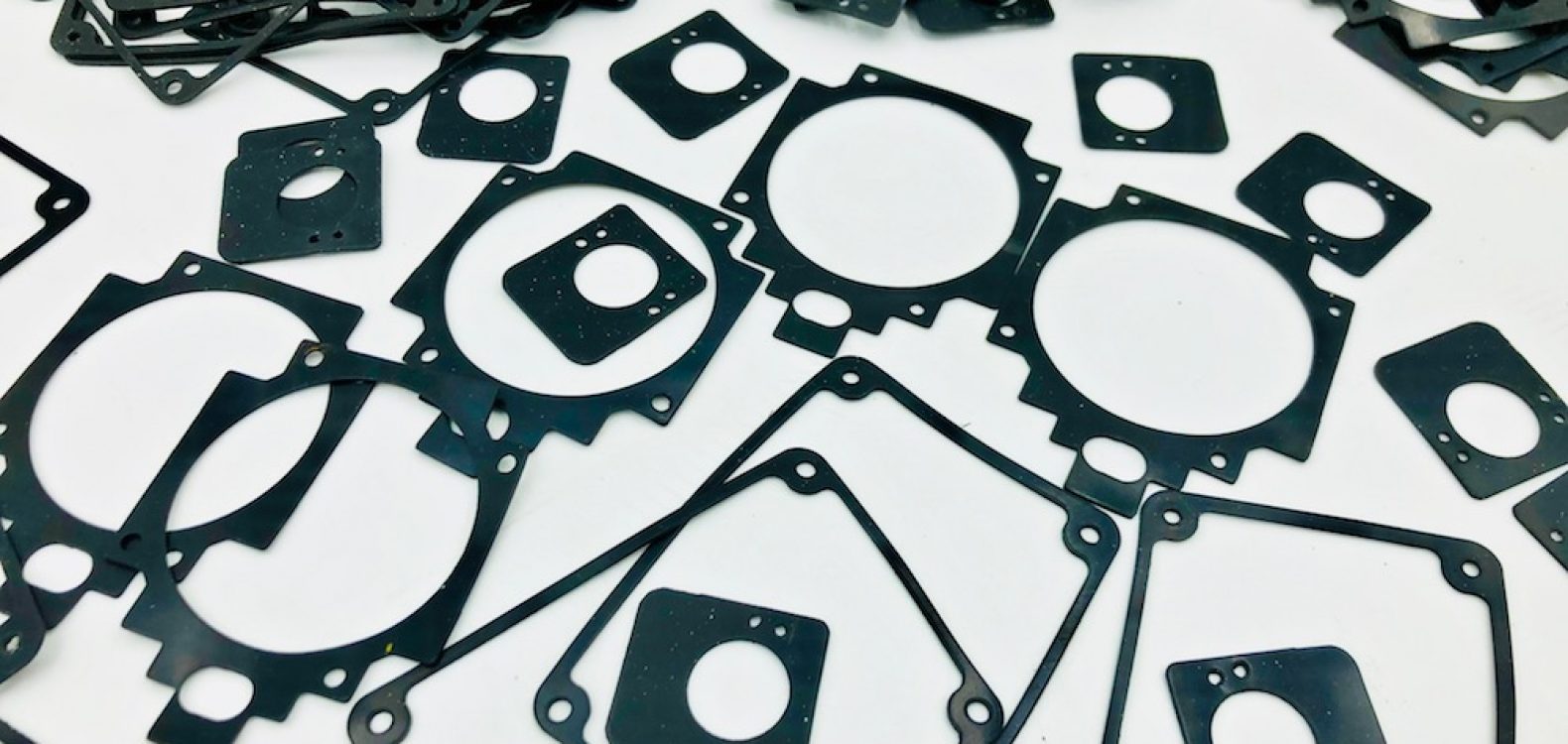

- PVC Material: The core material of both the pipes and the seals is PVC, a versatile thermoplastic known for its corrosion resistance, lightweight nature, and ease of installation. PVC pipes are formed through extrusion, while PVC seals are molded or fabricated to suit various sealing requirements.

- Elastomeric Sealing Elements: The sealing portion of PVC pipe seals is typically made of elastomeric materials such as EPDM (Ethylene Propylene Diene Monomer), Nitrile, or Silicone. These elastomers provide flexibility and resilience, ensuring a tight and durable seal.

- Flanges and Fasteners: PVC pipe seals often come with flanges and fasteners made of materials like PVC, stainless steel, or carbon steel. These components provide secure connections and ensure the seals stay in place.

Function and Benefits:

PVC pipe seals serve several essential functions in piping systems:

- Leak Prevention: The primary role of PVC pipe seals is to create a reliable and watertight connection between PVC pipes, effectively preventing leaks and the escape of fluids.

- Pressure Containment: These seals maintain the pressure within PVC pipes, ensuring that it remains consistent and within safe operational limits.

- Corrosion Resistance: PVC is inherently resistant to corrosion, making it an excellent choice for applications where exposure to corrosive substances is a concern.

- Chemical Resistance: Depending on the elastomeric material used, PVC pipe seals can resist a wide range of chemicals, making them suitable for use in chemical processing, industrial, and wastewater applications.

- Temperature Tolerance: PVC pipe seals can withstand a range of temperatures, making them suitable for both hot and cold fluid transport.

- Easy Installation: The lightweight nature of PVC components, including seals, simplifies installation, reducing labor costs and downtime during maintenance or installation procedures.

Applications:

PVC pipe seals find extensive applications across various industries and settings, including:

- Plumbing: In residential and commercial plumbing systems, PVC pipe seals ensure leak-free connections for water supply and drainage.

- Construction: PVC piping systems and seals are commonly used in construction projects for water distribution, drainage, and HVAC (Heating, Ventilation, and Air Conditioning) systems.

- Irrigation: PVC pipe seals are integral in agricultural irrigation systems, ensuring the efficient and reliable transportation of water to fields.

- Wastewater Management: In municipal wastewater treatment plants and sewage systems, PVC pipe seals play a vital role in preventing leaks and maintaining system integrity.

- Industrial Manufacturing: Industries that require the transportation of various fluids, such as chemicals, acids, or bases, rely on PVC piping systems and seals.

- Aquaculture: PVC pipes and seals are used in aquaculture applications for water supply, circulation, and drainage in fish farming facilities.

- Swimming Pools and Water Parks: PVC piping systems with seals are used in the construction and maintenance of swimming pools and water park facilities.

In conclusion, PVC pipe seals are essential components that contribute to the reliability, safety, and efficiency of PVC piping systems in a wide array of applications. Their resistance to corrosion, chemicals, and temperature variations, coupled with their ease of installation, makes them a preferred choice for fluid transport and containment solutions in both residential and industrial contexts. PVC pipe seals continue to be indispensable in modern infrastructure and industry.